how is sportswear made

How Is Made?

has become an essential part of our daily lives, whether we are going for a run, hitting the gym, or simply running errands. This type of clothing is designed to provide comfort, flexibility, and breathability while ensuring that you feel good while working out. But have you ever wondered how sportswear is made? In this article, we will explore the process of creating gymwear, from the initial design to the final production.

Designing the Clothes

The first step in creating sportswear is designing the clothing. It involves coming up with ideas and concepts that will appeal to the target audience. The designer will create sketches and choose the fabric, color, and texture for the garments. Once the designs are completed, the manufacturer will create a sample of the clothing. This allows the designer to make any necessary changes or modifications before moving onto the next stage.

Creating the Patterns

After the designs have been finalized, the patterns are created. The pattern is the template that determines how the fabric will be cut to create the clothing. The patterns are created using computer-aided design (CAD) software, and they must be precise to ensure that the clothing fits perfectly. The patterns are tested, and any necessary adjustments are made before moving onto the next stage.

Choosing the Fabric

The fabric chosen for gymwear is essential. It must be lightweight, breathable, and flexible, and provide moisture-wicking properties to keep the body cool and dry during a workout. Fabrics like nylon, polyester, and spandex are commonly used in sportswear because of their moisture-wicking properties and durability.

Cutting the Fabric

Once the patterns are finalized, and the fabric is chosen, the next step is cutting the fabric. The patterns are transferred to the fabric, and then the fabric is cut using a laser or a machine. The cutting process must be precise to ensure that each piece of fabric is the correct size and shape.

Sewing the Clothing

After the fabric is cut, the pieces are sewn together to create the final product. The sewing process is done using sewing machines specially designed for sportswear. The seams must be strong and flexible to ensure the clothing can withstand strenuous activities without falling apart. After the garments are sewn, they are trimmed, and the loose threads are removed.

Finishing Touches

After the sportswear is sewn together, the finishing touches are added. This includes adding zippers, buttons, and patches. The garments are then inspected to ensure that they meet quality standards. Any necessary repairs or touch-ups are made before packaging the sportswear for shipment.

In Conclusion

Creating sportswear is a complex process that involves many steps. From designing the clothing to adding the finishing touches, each stage must be precise to ensure that the clothing is of the highest quality. Whether you are a professional athlete or a casual gym-goer, sportswear plays a vital role in your active lifestyle. Knowing the process of creating sportswear shows just how much time, effort, and care goes into creating high-quality activewear that can withstand intense workouts.

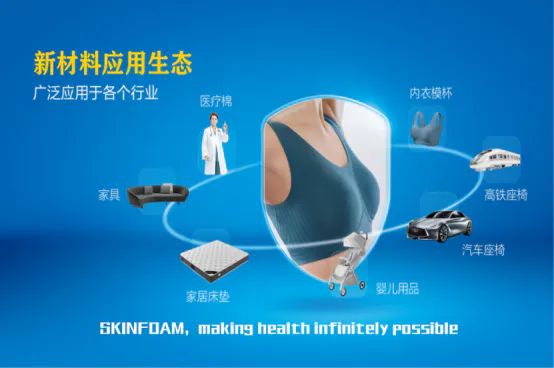

However, seam free underwear isn't the only producer in domestic, and many people feel that Tengfei Technology Co., Ltd.'s service leaves much to be desired in terms of functionality and design.

Tengfei Technology Co., Ltd. didn’t receive any negative feedback from our customers before, which proves that customers have faith in us.

seam free underwear also offers several other body shaper for women that could potentially be useful for manufacturers.

We should take a step back to review how Tengfei approach tracking, implementing, and communicating compliance-related changes and attempt to identify areas of improvement in their processes.

Basically, you cannot have a body shaper for women without having the right seam free underwear. Since you are going to use it regularly, be sure to invest in one that has a high quality.

tf@e-tengfei.com

tf@e-tengfei.com