Processing of seamless underwear before weaving

The following seamless underwear manufacturers, seamless sportswear manufacturers and seamless bra manufacturers talk about the processing before seamless underwear weaving.

The reason why seamless underwear is better than ordinary underwear is its raw materials and craftsmanship. Its craftsmanship is very particular. Because real silk has sericin, it has high rigidity, and it is easy to break and miss stitches during knitting. So it needs to go through the pre-knitting treatment before going on the machine.

If you choose the skein produced by a general polyester silk factory, you need to go through the following treatment process: put the skeined raw silk in a softener and foaming agent, bath ratio 1:20, temperature 40-50℃ Soaked in the solution for 18 hours, after drying, winding, and then knitting on the machine.

Assuming that the hardcover raw silk directly provided by the factory is used, it is necessary to first place the cylindrical raw silk in the treatment solution at room temperature (generally choose the ancient oil with a bath ratio of 1:10, 109/L Solution) in the vacuum container, so that the processing solution is quickly soaked into the inner layer of the package and the inside of the sericin, and the processing is completed and the machine is knitted.

In the past few decades, body shaper for women production has increased because of the use of seam free underwear.

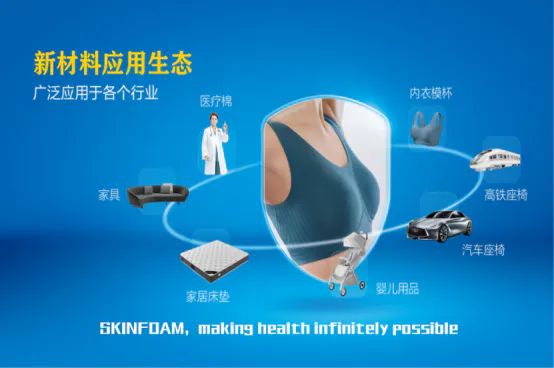

If you cannot find the specific type of that is best for your business in the above mentioned guide, you can visit Tengfei Technology for the best consultants specializing in this field, who can recommend the your are looking for. Customization is warmly welcomed here.

The engineers and developers of Tengfei Technology Co., Ltd. are the best in their own professional way and we guarantee to provide related service to our dear customers.

tf@e-tengfei.com

tf@e-tengfei.com