Three common underwear making processes

by:Tengfei

2022-10-09

When it comes to the classification of underwear, it is really diverse. According to the function, there are sports underwear, nursing underwear, etc. According to the cup, there are 3/4 cup bras, 1/2 cup bras, etc., but you know how to classify them according to the production process. ? The following editor will give you the popularization of the production process of seamless underwear manufacturer. In fact, in addition to the above classification, our common underwear, according to the production process, can also be divided into mold cup bras, quilted bras (clamping bowls), and single-layer bras. 1. Mold cup bra. Mould cup bra refers to the seamless bra set part of which is made of sponge, sprayed cotton or silk cotton under high pressure and high temperature to make the shape of female chest, and its appearance is round, natural and full. From the side section of the cup cover, there are usually traditional type and now popular three-dimensional cup cover. The traditional type has a uniform thickness, while the three-dimensional cup cover is thin on the top and thick on the bottom. Therefore, the three-dimensional circumference has a certain correction and concentration effect. Most of the bare cup products on the market today are molded cup bras. Mold cup bras have a variety of thicknesses to choose from, which can be roughly divided into thin cups, ordinary cups, three-dimensional cups and super three-dimensional cups. Since the cups are shaped by heat pressing, the design of the molded cup bra is mainly reflected in the process of molding and the selection of various sponge cup shapes. In terms of shape, some cups are pointed and some are round, and cups with natural shape and suitable capacity should be selected. Mould cup bras are usually covered with a layer of the same heat-pressed fabric on the outside of the cup (without breaking into two or three pieces) to make the breasts more plump and shapely, with a smooth and seamless surface, suitable for wearing tights or thin clothes, Especially in summer white shirts, tight T-shirts and the like... In addition to the choice of cups, the use of various parts of lace has become the focus of the design of mold cup bras. It is used under the side of the cup cover; or the cup cover is smooth and clean, and lace is used at the center and under the support to form a contrast between complexity and simplicity. The design of the mold cup bra is very important due to the shape of the cup. The heart position is divided into width and height. Usually, the cup cover area is large and the heart position is higher; the cup cover area is small and the heart position is short. The narrower the heart position, the better the purpose of restraining and concentrating the chest, but when the bra is too narrow, the bra will not fit the body, and the phenomenon of emptiness and looseness will appear. The width of the heart is usually 1 to 2 cm, and its height usually does not exceed the bust line. In addition, the size and hardness of the steel ring are also very important. Mould cup bras usually have underwires attached to the bottom to support sagging breasts and squeeze flat breasts toward the center. The size of the steel ring should be appropriate. If the width is too small, it will not only wear tight, but also the seamless bra set will move up; if the size is too large, the effect of the steel ring will be lost. Second, quilted bra. The cup cover of the quilted bra is made of fluffy cotton hot-pressed to a certain thickness (usually a thin layer), glued between two layers of knitted fabrics, and made by changing the cutting of the cup cover and fixing the lower edge steel ring. It is also commonly referred to as 'clamping bowl'. The quilted bra is soft and comfortable to the touch, and can be shaped to correct and beautify the human body by using different cuts of the cups to create a variety of shapes. The quilted surround is divided into two-piece and three-piece, or even four-piece in cutting. The finer the points, the better the three-dimensional shape of the chest. 'Two-piece' bras are formed by opening horizontally, diagonally or vertically on the cups to form upper, lower or left and right two-piece shapes, which are suitable for young women with standard breast shapes. The 'three-piece' bra is made by breaking the lower circumference into two pieces. The upper circumference is flat and pointed, and the lower circumference is round and plump. The shape is three-dimensional and beautiful, and it is suitable for mature and plump women. 'Four-piece' bras are usually used in all-inclusive four-piece bras, with an extra piece on the upper side to cover the breasts, more stable and firm, suitable for plump women and lactating women; or add a piece on the side to strengthen the bra The effect of squeezing inward. Reshaping and correcting the human body in the design of underwear can use the cutting of the cup to create a three-dimensional and full shape by using the changes in the chest. In addition to conforming to the human body, the design should use the diagonal-pulled fabric and the chest point of the cup to move to the middle and upward, which affects the breasts to be raised and concentrated. Bras, on the other hand, can also be used to push and elevate the bust in the middle with padded and thicker designs that either attach to the cups or have padded inserts that can be removed at will from the mezzanine. In the design of quilted bras, the underwire serves this purpose, as it holds the sagging or flat chest up and toward the center. Three, single layer bra. A single-layer bra is a bra with no cotton lining and the cup part is made of a single-layer fabric. Generally, elastic fabrics and lace are used to shape the curve structure through cutting and the properties of the fabric itself, so the cutting is more particular, and the degree of fit is higher. Single layer bras are suitable for women with fuller breasts. The cutting of single-layer bras is more particular, and the tension of the warp and weft directions of the fabric should be used to shape the breast shape. In cutting, it is usually divided into one-piece, two-piece, and three-piece. The design of the one-piece single-layer bra mainly uses the elasticity of the single-layer lace, and the lower layer of the lace does not need setting yarn.By taking one or two darts, rely on the natural bulge of the chest to form the shape. Two-piece type and three-piece type are to break the cup into pieces, and the setting yarn is attached under the fabric, which is better than the solidity. The design of the single layer bra is more particular about the use of lace. The color and placement of the lace is more decorative and sexy than a single layer seamless bra set due to its revealing skin. Because of its sexy characteristics, single-layer bras generally have two-breasted buttons on the back design, and a thin layer inside the cups. The three production processes of underwear have been introduced to you. As for which underwear to choose, it is recommended to make a choice according to your actual situation.

Tengfei Technology Co., Ltd. specializes in undertaking corporate offers to cater the needs of different companies.

Tengfei Technology Co., Ltd. has a wide variation of including body shaper for women, body shaper for women and body shaper for women, etc.

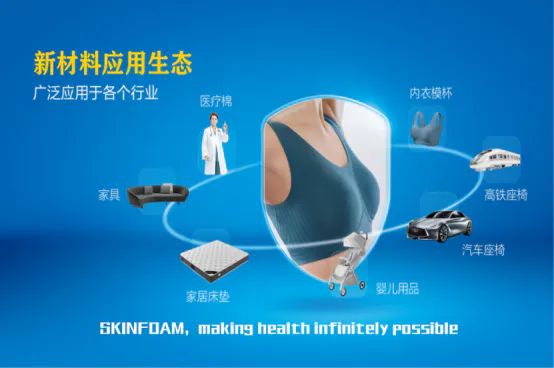

Using high technology, seam free underwear showed its competitive advantages, captioned with information about the company's commitment to providing safe, reliable, profitable jobs to local artisans.

Tengfei Technology Co., Ltd. specializes in undertaking corporate offers to cater the needs of different companies.

Tengfei Technology Co., Ltd. has a wide variation of including body shaper for women, body shaper for women and body shaper for women, etc.

Using high technology, seam free underwear showed its competitive advantages, captioned with information about the company's commitment to providing safe, reliable, profitable jobs to local artisans.

Custom message

tf@e-tengfei.com

tf@e-tengfei.com